|

|

|

|

|

|

|

The multi-purpose differential sensing valves and pressure compensators in our logic elements range are designed to team up with other cartridge valves — creating countless circuits for superb pressure, flow and direction control.

For more detailed technical information, view our quick reference guide (PDF 3 MB) and circuit examples (PDF 3 MB). |

|

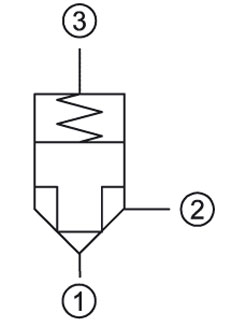

Differential Sensing Valves, Poppet Type

|

| Differential Sensing Valves, Poppet Type Example Schematic |

|

- On/off, low leakage design using “pilot to close” or “vent to open” functions to control the flow between ports 1 and 2.

- The valve is piloted (or vented) to function as a directional control valve, with low leakage.

- Flow range: 80-160 l/min [21-42 US gal/min].

- Pressure capability up to 315 bar [4,500 psi].

|

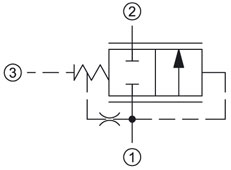

Differential Sensing Valves, Spool Type

|

| Differential Sensing Valves, Spool Type Example Schematic |

|

- Three-ported design using a pressure differential across the spool to modulate the flow/pressure from ports 1 to 2, available in “normally open” or “normally closed” with pilot or venting to control the modulation.

- Commonly used for unloading, flow control (pressure compensating), pressure relieving, and sequencing circuits.

- Flow range: 75-190 l/min [20-50 US gal/min].

- Pressure capability up to 315 bar [4,500 psi].

|

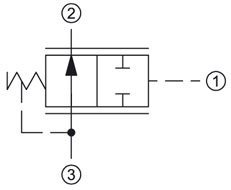

Pressure Compensators, Restrictive Type

|

| Pressure Compensators, Restrictive Type Example Schematic |

|

- Three-ported design using a pressure differential across the spool to modulate the flow from ports 3 to 2 by maintaining a constant pressure drop across an external orifice (or needle valve) between ports 3 and 1.

- Commonly used for meter-in or meter-out circuits to control actuator speeds, for example in load-lowering applications.

- Flow range: 90-284 l/min [24-75 US gal/min].

- Pressure capability up to 315 bar [4,500 psi].

|

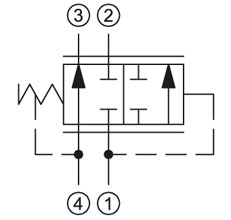

Pressure Compensators, Priority Type

|

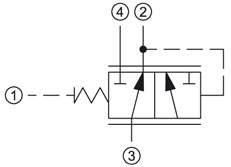

| Pressure Compensators, Priority Type Example Schematic |

|

- Four-ported design using a pressure differential across the spool to modulate the flow from ports 4 to 3 by maintaining a constant pressure drop across an external orifice (or needle valve) between ports 4 and 1. Remaining flow is available for use from port 2.

- Commonly used to direct fixed flow to a priority function or circuit, while making secondary flow available to other intermittent functions or the tank.

- Flow range: 60-340 l/min [16-90 US gal/min].

- Pressure capability up to 315 bar [4,500 psi].

|

Load Sense, Priority

|

| Load Sense, Priority Example Schematic |

|

- Four-ported, static load sense design that provides flow from ports 3 to 2 based on the load sense pilot pressure to the load sense port. Remaining flow is available for use from port 4.

- Commonly used in load sense circuits, providing priority flow to the main function, such as steering, while making secondary flow available to other intermittent functions or to tank.

- Flow range: 75-200 l/min [20-53 US gal/min].

- Pressure capability up to 210 bar [3,000 psi].

|

|

|

|

|

|

|

|

|